Generative Artificial Intelligence

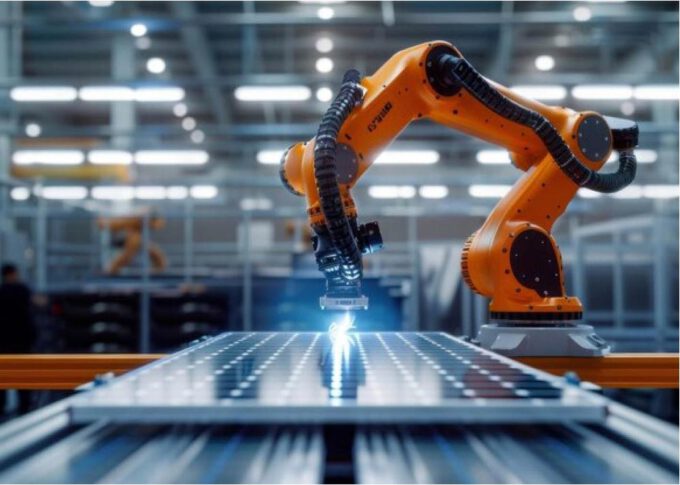

With 20 years of experience in robotics and artificial intelligence applied to manufacturing processes, we have witnessed firsthand how AI is transforming the industry. The implementation of AI in manufacturing not only promises to increase productivity and quality, but also to reduce operational costs. However, this process comes with a series of challenges that companies must overcome to fully harness this technology.

#Tech #Industry #Economy

Challenges:

1. Integration with Existing Infrastructure: Implementing generative AI in established manufacturing systems can be complex. Many plants operate with legacy systems that are not designed to handle the demands of AI, requiring significant upgrades or adaptations. However, there are already low-cost systems available that convert traditional manufacturing machines into smart manufacturing machines.

2. Lack of Qualified Personnel: Successful implementation of generative AI requires staff with specialized skills. Improvisation or the absence of experienced providers and personnel can compromise both the technology and the talent required for success.

3. Security and Privacy: The intensive use of data and advanced algorithms poses challenges regarding cybersecurity and the protection of sensitive information. Companies must implement robust security measures to guard against potential vulnerabilities.

4. Data Quality and Availability: Generative models require large volumes of high-quality data for training. Ensuring data is accurate, complete, and representative is a challenge, especially in manufacturing environments with fragmented or legacy data.

Benefits:

Generative artificial intelligence offers several benefits for the manufacturing industry. One of the main advantages is the optimization of production lines. With generative models, companies can create and test multiple production line variants in a fraction of the time it would take using traditional methods.

Generative AI can also improve production planning by simulating different scenarios and optimizing resource usage. It also enables predictive maintenance, as models can forecast machinery failures before they occur, reducing downtime.

Another benefit is large-scale customization, allowing companies to tailor products to customers’ specific needs without significantly increasing costs. This, in turn, can enhance customer satisfaction and open new market opportunities.

In summary, generative AI can elevate manufacturing to a new level of efficiency, flexibility, cost reduction, and competitiveness. In Ciudad Juárez, Mexico, several medical, automotive, and electronics manufacturing plants are already using AI models in their processes—from material reception and real-time production line monitoring to operational management and deliveries.

Today, company organizational charts are becoming hybrid, where artificial intelligence and human personnel play a key role in the development and evolution of industries.

Does your industry already have a hybrid organizational structure?

Javier Acosta

javier@imechatronic.com